Geoinvestigate have been providing ground stability mining reports for over 20 years and Coal Mining Risk Assessment or CMRA since its introduction by the Coal Authority in 2011. This article is intended to help those making a planning application understand what CMRA is.

Coal mining risk assessment CMRA and what you need to know when making a planning application.

Simply the purpose of Coal Mining Risk Assessment is to avoid recent events like this

and this

This article is presented in 14 parts

1.What hazards does my development face from coal mining legacy in the UK

2.Types of coal mining – mine shafts, adits, underground workings & surface pits/opencasts

3.Dangerous mine gases

4.Safe drilling investigation in coal & mine workings

5.How do I find out if my developments in a HIGH RISK area or DHRA

6.What’s a CMRA

7.What’s in a Geoinvestigate CMRA

8.What type of CMRA do I need to order

9.What’s the outcome of a CMRA report

10.Can I still get planning permission if my CMRA recommends further investigation

11.How do I order a CMRA from Geoinvestigate

12.What information do I need to provide to start a CMRA

13.How long will a Geoinvestigate CMRA take

14.What happens to my CMRA when I submit it to the Local Authority

1 What are the coal mining legacy hazards in the UK?

Throughout the UK over 2 million buildings are affected by shallow coal mines workings, (approximately 8%), and of these 130,000 are known to lie within 20m or 1 or more shafts. Although proportionally small, on average 15 shaft collapses occur each year and the trend seems to be that shaft collapses are on the rise perhaps connected to our changing weather. With over 172,000 mine entries and 26,000 km2 of underground workings the UKs coal legacy poses serious hazards to existing development and future house, school and commercial building.

The problem becomes even greater when all the other mining activity in the UK covering 60 minerals is combined. In this regard there are believed to be 405,000 mine shafts in this country including ancient flint workings dating back to the Neolithic and Roman times.

So to protect you and your families safety and the value of your property if the new house, kitchen extension, office or factory unit you are going to build is located on a coal mining Development High Risk Area (also known as a DHRA) you will need a specialist Coal Mining Risk Assessment report.

You will also need a (CMRA) from a company like Geoinvestigate to get planning permission from your local planning authority (LPA) and the UK Coal Authority (CA). Your LPA will send your CMRA to the CA for checking and they have the power to reject it resulting in a knock-on delay on your planning application and the start of your building works.

A CMRA is required because there are various hazards that can arise when you build in the former coal mining areas of the UK including Central Scotland, North East and North West England, Yorkshire, The Midlands and Black Country, South Wales, Bristol and Somerset.

The main hazards to development are from rapid building collapse or slower building subsidence caused by unstable land connected with mine entries or mined-out ground beneath a site. Gardens, parkland and roads can also be effected. The greatest risk to the public is from abandoned mine shafts, mine adits, mine workings and surface pits or opencasts in this order.

The closer mine workings are to surface the greater the risk they pose to development. Shallow mine workings < 30m depth below the surface and very shallow workings are of particular concern.

Toxic, suffocating or explosive mine gases can also pose very serious problems for building development and public safety.

[caption id="attachment_31425" align="alignnone" width="476"] Demolition of 5 new homes because of mining subsidence at Bellway Homes, Bayfield Estate, West Allotment near Newcastle [/caption]

Demolition of 5 new homes because of mining subsidence at Bellway Homes, Bayfield Estate, West Allotment near Newcastle [/caption]

2 Types of coal mining

Workings

Coal seams can be worked by underground mining called ‘workings’ or large surface excavations called opencasts or open pits. In underground mining a coal seam can be completely or partially removed. The former is known as total or longwall mining and causes large areas of mined-out ground to collapse and close-up quickly. This can be beneficial because soon after mining has finished the ground surface is unlikely to move appreciably. Not everything is mined out as large areas of coal may be left untouched to safeguard important buildings or to protect the mining operation itself from complete collapse. Coal may also remain unmined in areas of geological faulting where the rock is fractured and too unstable and unsafe to work or where faulting has caused a coal seam to be missing.

Alternatively in room and pillar working (also known in various parts of the country as pillar and stall, stoop and room or board and pillar mining) large underground chambers or cavities may remain open for many years after mining has ceased supported by remnant coal pillars. This typically older type of mining was very common across large parts of the Scotland, England and Wales and often took place at shallow depth.

Mined cavities or chambers may have been purposefully infilled, hand stowed or packed by miners many years ago as part of routine mining activity both to minimise the waste that needed to be taken to surface and to reduce surface mining subsidence.

Consequently past or ancient underground mine workings may now have completely collapsed or they may remain partially or fully open. Ground which has been mined may resemble a cellular honeycomb pattern or a more regular checkerboard layout pattern of coal pillars separated by completely open or partially infilled dry or flooded voids, cavities, caves or caverns.

Underground coal mine workings can be small perhaps 1 ½ to 2 feet (0.5 or 0.6m) in height – the width of a boy or a man’s shoulders when working with a pick on his side but are typically 1m, 2m or 3m high and sometimes > 8m where the coal seam was particularly good, one of the best examples being the Thick Coal Seam in Dudley in the Black Country which was reported to be up to 10 yards thick (9m) in places. Large mine caverns were formed in the Black Country around Birmingham not only in coal but also in the underlying Limestone giving rise to major ground instability problems in both. Large areas of land subsided forming ponds and lakes called ‘flashes’ while some buildings were tilted and distorted. Occasionally whole streets were damaged or collapsed and were subsequently demolished. Building subsidence still occurs today in the Black Country caused by the collapse of mine shafts and the movement of near surface large open mine cavities.

The Crooked House Pub in Dudley is one of the best surviving examples of mining subsidence in the Black Country while another is The Tilted Barrel.

caused by historical coal mining subsidence

Mine Shafts, Adits, Drifts and Levels

An adit is a horizontal or inclined entry connecting to a mine tunnel and mine workings. Also called a level or drift, an adit often leads into a hillside while a mine shaft is a vertical mine entry with a headgear or head frame for lifting and lowering workers and materials.

Surface coal mining or ‘opencasting’ leaves very large pits which are typically restricted to much less than 150m depth in the UK. These pits may be subsequently restored/infilled with landfill and/or the materials that were originally excavated from the site minus the coal which has been removed. Several coal seams may be removed together in a deep opencast. Today you might hardly recognise a former opencast site because it has been fully restored and landscaped for parkland or it has been developed as a housing estate. Restored or infilled opencasts present their own problems including contamination from the hazardous materials filling them, dangerous landfill gases from bio-degradable components of the waste and settlement. Even if a former opencast site has been infilled with rock debris buildings located on it can be liable to long term settlement and there is the risk that the base and sides an infilled opencast may be underlain by underground workings.

Shallow mine workings are defined by the UK Coal Authority as mine workings of less than 30m depth. In the UK the main concern from coal mining legacy is shallow and very shallow mine workings and to a lesser degree the collapse of mine shafts. In the UK over 2 million buildings are affected by shallow coal mine workings.

Normally mine shafts pose most risk when they are close to or under a building and much less when they are further away. Their risk is much reduced if rock lies close to surface and the upper part of the shaft is not in loose soil which unlike rock has the potential to collapse many metres beyond the shaft. Even within 20m of a property mine shafts can have can have an impact on safety and property values. Because of the risk of sudden large collapse posed by mine shafts they need special consideration.

The extract below shows just how many known or recorded mine shafts there are in the UK. The whereabouts of tens of 1000s more mine shafts are unknown and they remain hidden below roads, parks, playgrounds, schools, industrial buildings and housing estates today. Very occasionally they collapse without warning as occurred on a housing estate in Moffat Scotland in early 2016.

3 Dangerous mine gases

Although explosive and toxic mine gases such as methane and carbon dioxide are rarely problems in the UK, because they are potentially very dangerous, they and other mine gases should be treated with the utmost caution. For this reason and because there is usually very little site specific data on mine gas it is sensibly safer to assume that mine gas could exist at each and every development site until proven otherwise at the site under consideration preferably by on-site gas testing or a conclusive negative outcome from a desk top CMRA.

Because of the serious risk posed by mine gas The UK Coal Authority and the UK Health & Safety Executive (HSE) consider that the investigative drilling of coal or mine workings should be carried out using only water flush as this is by far the safest way of avoiding the creation or releasing dangerous gases which may migrate upwards into nearby buildings placing their occupants at risk. In 2005 mine gases released during drilling probably caused the death of an elderly couple as this extract from the British Drilling Association (BDA) Feb 2012 Newsletter describes.

Subsequently the UK Coal Authority have on several occasions stated that water flush drilling should be mandatory.

4 Safe drilling investigation of coal and mine workings

Drilling remains the only certain way of proving whether, or not mine workings and mine shaft hazards really exist beneath a site.

New small Microdrilling technology recently introduced into the UK site investigation market is faster, safer, cheaper and more environmentally and site friendly than big machine drilling of the past. In addition because of its much smaller size Microdrill can get into places the other drills can’t reach through narrow gates into gardens and backyards and side alleys.

In most built up areas in the UK only drilling with water flush is safe and the Coal Authority won’t issue a drill license for anything else but water. This is because water as shown in the table below is the safest way to drill coal and workings. Mud though safe is too messy.

5 How do I find out if my building is in a High Risk Area or DHRA?

Often the 1st time the public becomes aware that their new building development is in a DHRA is when they submit a planning application and are told by their LPA that they need a ‘Coal Mining Risk Assessment or CMRA’. Sometimes local council planning departments can unintentionally provide confusing information by suggesting that a ‘Coal Report’ is needed when in fact a more expensive specialist Coal Mining Risk Assessment or CMRA is required as part of the planning process in a DHRA.

This can happen even to architects and planning consultants. Being caught unawares like this and not submitting a proper CMRA with your planning application can result in costly delays to your application and delay the start of your building works.

If you are in doubt about whether your site falls in a DHRA or you want a 2nd opinion about the advice your LPA has given you in this regard – contact Geoinvestigate and we will check for you – free of charge!

You can also check if you are in a DHRA and require a CMRA by using the following links to the Coal Authority’s web site or with your local planning department.

https://www.gov.uk/guidance/planning-applications-coal-mining-risk-assessments

If your site falls in a DHRA you will need a Coal Mining Risk Assessment or CMRA.

If your site does not fall within a DHRA you do not need a specialist CMRA. You may still however require a standard coal mining search as part of conveyancing process to obtain a mortgage.

6 What is a CMRA?

A CMRA is a desk study exercise based on reviewing several different sources of information. No visit is made to the site to check the findings of the CMRA though a good CMRA should include viewing Satellite and Street View imagery as currently made freely available by Google. The purpose of the CMRA is identify a range of geohazards including

•Subsidence and collapse of mine entries and shallow mine workings.

•Unrecorded mine entries, soughs (mine water drainage) and workings.

•Emission of noxious or asphyxiating mine gases created by natural or human intervention.

•Spontaneous combustion of coal exposure to atmospheric conditions.

•Impoundment, unconsented discharge or uncontrolled release of mine water.

•Mine water recovery and rise.

•Pollution incidents resulting from mine water and contaminated shaft fill.

•Settlement associated with opencast mine backfill.

•Failure of slopes and tips comprising colliery spoil or waste.

•Mining related fissures and fault reactivation.

Not all these hazards will affect a site and typically the most important to consider in the CMRA are the collapse of nearby mine entries and shallow workings and mine gas.

Recently the likelihood of future mining occurring has been added to the list. While this may seem unquantifiable in reality it is in most cases inconceivable that extensive underground mining will ever take place again in the UK for the foreseeable future and this is the pragmatic response.

A CMRA has to be carried out by a ‘Competent Person’ Preferably this person should be a degree qualified geoscientist, mining engineer or mineral surveyor with some real mining experience. After all it’s about mining.

The CMRA report should provide an outcome with advice from the competent person on what measures (if any) need to be taken to safeguard your development from coal mining legacy. ‘Mitigation Measures’ as they are called may include

•Moving the building to a safer location within a site – not usually possible.

•Infilling shallow mine workings and shafts with cement grout and sealing shafts with a concrete cap.

•Prohibiting building over shafts even though they may have been infilled and capped.

•Designing special reinforced foundations and flexible buildings over mined ground.

•Carrying foundations below shallow mine workings or opencast backfill using deep columns or piles.

•Compacting or consolidating opencast infill.

•Excavating and removing shallow mine workings and off-setting the cost by selling the coal.

•Stopping gas entry into buildings using ventilated sub-floor voids or special impermeable gas membranes.

If the findings of the CMRA are uncertain the Competent Person may insist that additional information is obtained before a final outcome is reached and the report can be issued. This may include extending the desk study review and looking at mine abandonment plans and other historical mine records and possibly making a visit to the Coal Authority’s offices.

Alternatively the Competent Person may reach an outcome and issue their CMRA with the recommendation in the report that further exploratory probe drilling or trenching is carried to verify the presence or absence of coal seams, shallow mine workings or mine shafts within a site.

The completed CMRA report is upon submission to the LPA forwarded by them to the Coal Authority for review and comment by them. In many cases the findings of the CMRA will be accepted by the CA while in others the CA may raise ‘Substantive Concerns’ about the report in which case the CA may recommend that the CMRA desk study be reassessed and/or its scope extended or that additional intrusive site work including drilling is carried out.

In some instances the CA have been known to strongly criticise the quality of a CMRA report which in Geoinvestigate’s experience has perhaps in 1 or 2 instances led to a more pessimistic outcome than would have arisen had the CMRA been carried out properly in the 1st place.

The recommendation in a CMRA that extra intrusive site work be carried out would not normally preclude planning permission being granted with the condition that the extra work be completed at a later date before building starts. Depending on the results the Mitigation Measures outlined in the initial CMRA may be adopted or changed in the 2nd technical report by the same or another Competent Person. If the outcome of the 2nd technical report is found to be satisfactory by the CA any outstanding planning condition with respect to coal legacy will be removed by the LPA.

7 Whats in a Geoinvestigate CMRA?

Geoinvestigate’s CMRAs are fully compliant with Local Planning Authority, Building Control and Coal Authority requirements and are carried out by fully Competent Persons.

Geoinvestigate’s CMRAs follow UK Government and Planning recommended methodology and reporting format for CMRA as set out in the following 2014 and 2017 Guidance Documents.

As recommended by the UK Coal Authority Geoinvestigate’s CMRAs are carried out by a Competent Person – in our case degree qualified professional Geoscience practitioners. Many of our technical staff also have Master of Science awards.

Geoinvestigate’s desk study CMRAs are usually based on an evaluation of the following range of information if available.

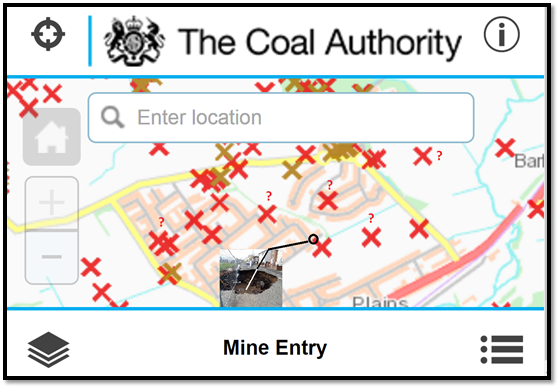

The Coal Authority coal mining starter report.

The CA’s online interactive map viewer service.

Historic Ordnance Survey maps dating back to the mid-1800s.

British Geological Society (BGS) 1:50000 or 1:636360 geological plans

BGS borehole archives.

Google Street View and Google Satellite site imagery

The 3 most important pieces of information used by Geoinvestigate in our CMRAs are the Coal Authority starter report, geological maps and nearby borehole records although it is not always possible to obtain boreholes.

Sometimes other relevant information including geological memoirs, special research reports and mine abandonment plans may be referred to as well though there is likely to be an increase in cost of the CMRA when more detailed assessment is required

A CMRA from Geoinvestigate will both identify the hazards your property faces from local coal mining legacy and tell you what you need to do to develop your site safely.

8 What type of CMRA report should I order? – Non-Residential or Residential?

In most instances when you are putting up a new building or extension no matter how small it is or whether its’ for residential or commercial end-use you will require a ‘Non-Residential’ otherwise known as a ‘Commercial’ or ‘Development Site’ coal mining report.

Strictly speaking a ‘Residential’ CMRA should is only obtained for the purpose of house conveyancing and in most cases is NOT appropriate for a stand-alone new building development.

All residential extensions to an existing home eg kitchen, bedroom, lounge and conservatory are all exempt and do not require a CMRA.

However if you are building a commercial extension on to your home such as a shop, multiple occupancy office or hairdressers you will require a commercial CMRA.

Even if you are building a SINGLE new house in your garden or on land which you have purchased with the intention of selling, renting the building, or living in it yourself as a family home you will still need a Non-Residential or Development Site CMRA. This is because it involves stand-alone new building development on land which was previously unoccupied.

You will definitely require a Non-Residential/Commercial CMRA if your building is an office, factory extension, industrial unit or even a small business annexe connected to an existing residential property or you are building multiple housing units.

In special cases a residential report will be acceptable e.g. when you are converting a commercial building to residential, a barn to housing, or you have demolished a building and are erecting a new house over exactly the same footprint.

The UK Coal Authority clearly stipulate what type of report you require and this information is provided on Geoinvestigate’s online CMRA ordering site.

It’s important to get this right because there have been instances where a LPA or Building Control have rejected a planning application because the CMRA accompanying it does not include the correct CON29M starter report. In addition the insurance cover the Coal Authority provide may be made invalid if the CMRA includes the wrong type of report.

9 What is the outcome of a CMRA report?

The starting point of a CMRA is that the site has been identified as a development high risk area. Therefore at the start of the investigation the risk from coal mining legacy is assumed to be POTENTIALLY significant.

The purpose of the CMRA desk study is to confirm whether the stability risk to site is NEGLIGIBLE or LOW in which case nothing further needs to be done or that it is a significant risk requiring further investigation by drilling and/or special foundations and/or the infilling of mine cavities with cement grout or moving the building onto stable land.

The need for further desk study work or intrusive investigation occurs where the outcome of a CMRA is uncertain as is often the case. Examples of this might be uncertainty about coal outcrop position shown of the geological map and the depth of coal beneath a site, whether the coal is minable, coal and mine working thickness, what impact geological faulting has on coal depth and minability, drift and bedrock depth and the position of mine shafts and adits, whether they are treated or untreated.

To some extent the Coal Authority have added to the uncertainty with their standard caveat phrases provided in their coal mining reports and risk assessment guidance.

The CA define Probable Workings as – “underground workings for which no recorded plan exists but where IT IS LIKELY that workable coal at shallow depths HAS BEEN MINED before records were kept”.

“However the property is in an area where the Coal Authority believe there is coal at or close to the surface. This coal may have been worked at some time in the past. The potential presence of coal workings at or close to the surface should be considered…….”

“There may however be mine entries/additional mine entries in the local area which the Coal Authority has no knowledge”

A competent person carrying out a CMRA would take heed of these warnings and the consequences of ignoring them.

To mitigate the risk highlighted by the CMRA the following several options are available to the competent person.

Risk Mitigation Options

1.Further desk study including obtaining mining plans and talking to local mining experts

2.Move building to a safer part of site where there is no risk

3.Check ground conditions with boreholes and /or excavations and review risk

4.Belt and braces building design – reinforced strips, foundation slabs and rafts, flexible structures.

5.Stabilise workings by grouting.

6.Excavate and remove coal and mine workings.

Mitigate risk by either moving the building to a safer part of the site or by adopting expensive, special foundation and/or building design measures with gas exclusion measures. Usually moving a building is not feasible.

Alternatively carry out exploratory drilling or excavation works at site and confirm whether special foundations and/or ground treatment and/or gas exclusion measures are needed.

Drilling is placed in the list ahead of special building design for obvious reasons. Without drilling you normally can’t make a decision with confidence on what follows next whether its special foundations grouting or bulk excavation.

In several instances Geoinvestigate has found that when drilling has been carried out as a CHECK on a CMRA this has shown that the expensive foundation design which followed the CMRA outcome was in actual fact completely unnecessary. Workings were either absent or lay too deep to affect the stability of the new building and the robust raft which cost 20K for a 4 bedroomed detached house was not needed. In fact only normal foundations were required. The cost saving resulting from now needing to do nothing but normal foundation design far outweighed the expense of drilling – making the client very happy.

10 Can I still get planning permission if my CMRA recommends further investigation?

Even though the CMRA may recommend further work there is no reason why planning application should be refused by your LPA providing the work is carried out a later date. This is called CONDITIONAL planning permission and is not an uncommon situation. You must make sure however that you do carry out the work subsequently and that a 2nd report or update on its outcome is formally submitted to your LPA so that they can remove the conditions.

11 How do I order a CMRA from Geoinvestigate?

You can order a CMRA online from Geoinvestigate by using the link to our web site below –

www.geoinvestigate.co.uk/cmra-lp/

Alternatively you can speak one of Geoinvestigate coal mining team and we will do the rest. Email us at ross.nicolson@geoinvestigate.co.uk or Free Call 0800 1712011.

Full payment is required up front upon ordering and there is NO REFUND once an order is placed.

Secure payment can be made online using Worldpay or we can send you a secure online link or take payment over the telephone.

12 What information do I need to provide?

•Site location address & post code. Grid coordinates if available

•Boundary plan of the plot

•Location of the new building within plot – if known

•Description of development – single house, multiple housing, building extension, factory etc

•Any known history or on mine working problems in the local area – if known.

If you don’t have very little information Geoinvestigate can help you locate your site using Google Satellite imagery.

13 How long will a Geoinvestigate CMRA take?

A CMRA from Geoinvestigate normally takes about 5 to 8 working days from placing an order. If the report is URGENT a quicker turnaround may be possible subject to an additional fee.

14 What happens to my CMRA when I submit it to the Local Planning Authority?

Your LPA forward your CMRA to the UK Coal Authority for checking by their technical experts. That is why your CMRA has to be carried out by a competent person. The CA will either accept the findings of the CMRA or reject it. If they reject or have “Substantive Concerns” about it your LPA will write to you advising you of this outcome and providing you with the CAs response explaining their reasons for rejecting it. They may ask the applicant to review the information again or to obtain further information such as mining plans. In 2 cases referred to Geoinvestigate out last year the CA specifically asked that drilling be carried out. This resulted in delay to the start of both projects and could have been avoided if a more competent person had been appointed to carry out the CMRA in the first place.

If planning permission is conditional upon carrying out further coal mining legacy investigation the 2nd technical report describing the outcome of the intrusive drilling or excavation work will be sent to the CA for checking once again. If satisfactory the CA will write to the LPA advising that the condition is removed.

If you need a Coal Mining Risk Assessment CMRA contact Geoinvestigate for a quote or simply order online from us